biodegradable Silage Stretch Film, Biodegradable Silage wrapping film,compostable Silage Stretch Film Wholesale

| Product name | Biodegradable Silage Stretch Film |

| Raw material | PBAT+PLA |

| Size | 45cm x 1500m or customized |

| Color | Clear or customized |

| Printing | no |

| packing | customized |

| certificate | EN13432 , BPI , OK Home Compost , AS-4736 ,AS5810, FDA,BSCI |

| MOQ | one ton |

| Deliver time | within 20days |

Silage Stretch Film: High-Performance Product Backed by Strong Factory Support

Our silage stretch film is a professional solution for efficient forage preservation, and its quality and supply stability are guaranteed by our leading manufacturing strength, making it a reliable choice for global livestock and agricultural clients.

一、Product Core Advantages

1.Superior Silage Preservation Effect:

Adopts a high-barrier PBAT+PLA composite formula to create an airtight environment, promoting anaerobic fermentation, locking in 90%+ of forage nutrients (protein, moisture), and preventing mold growth—keeping silage fresh for 6-12 months.

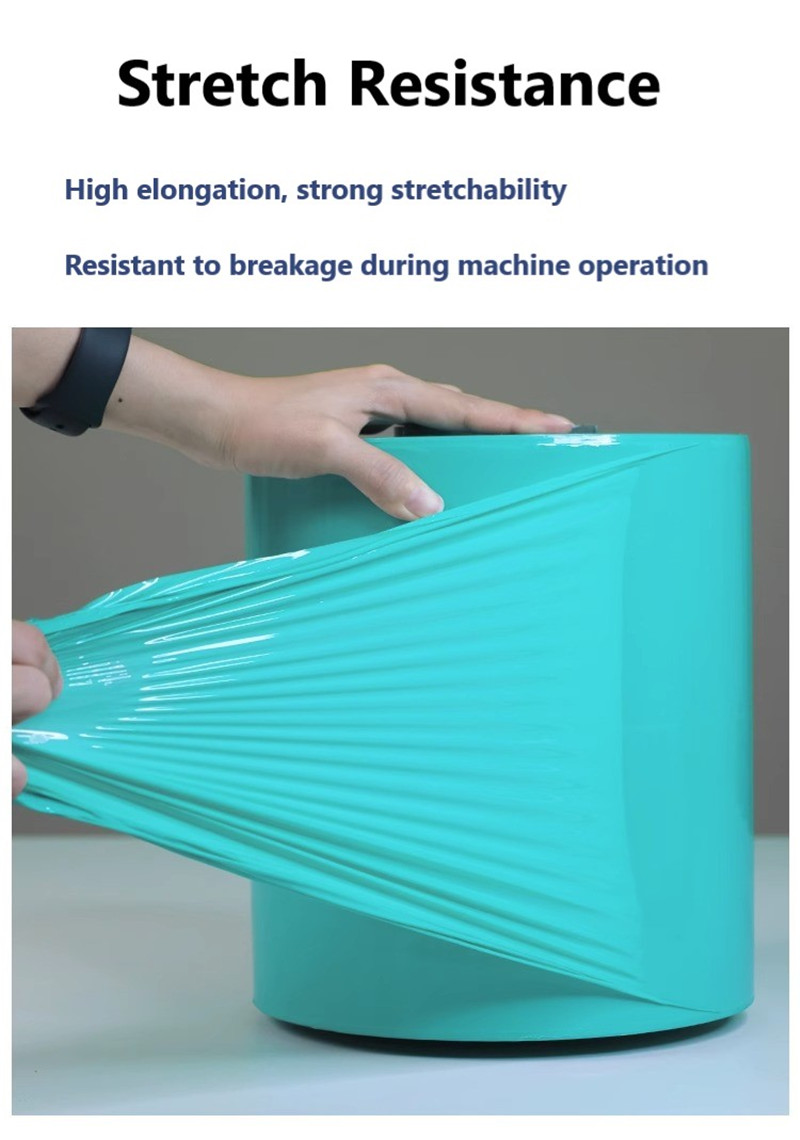

2.Excellent Mechanical Performance:

High elongation rate (up to 500%) for tight, wrinkle-free wrapping on large bales;

Strong tensile strength and puncture resistance, withstanding machine wrapping operations without breakage and resisting scratches from sharp forage or animals.

Wide Adaptability: Suitable for various climates (withstands -20℃ to 60℃) and forage types (grass, corn, alfalfa), meeting the needs of different regional farms.

二、Factory Strength Support

1.Large-Scale & Efficient Production Capacity:

Equipped with 8 sets of advanced 3-5 layer co-extrusion lines, achieving an annual output of 12,000+ tons—capable of fulfilling bulk orders (e.g., 500-ton orders delivered within 15 days) to avoid supply delays.

Supports flexible customization: Adjust film thickness (25-50μm), width (500-1200mm), and additive formulas (e.g., enhanced UV resistance for high-altitude areas) based on client needs.

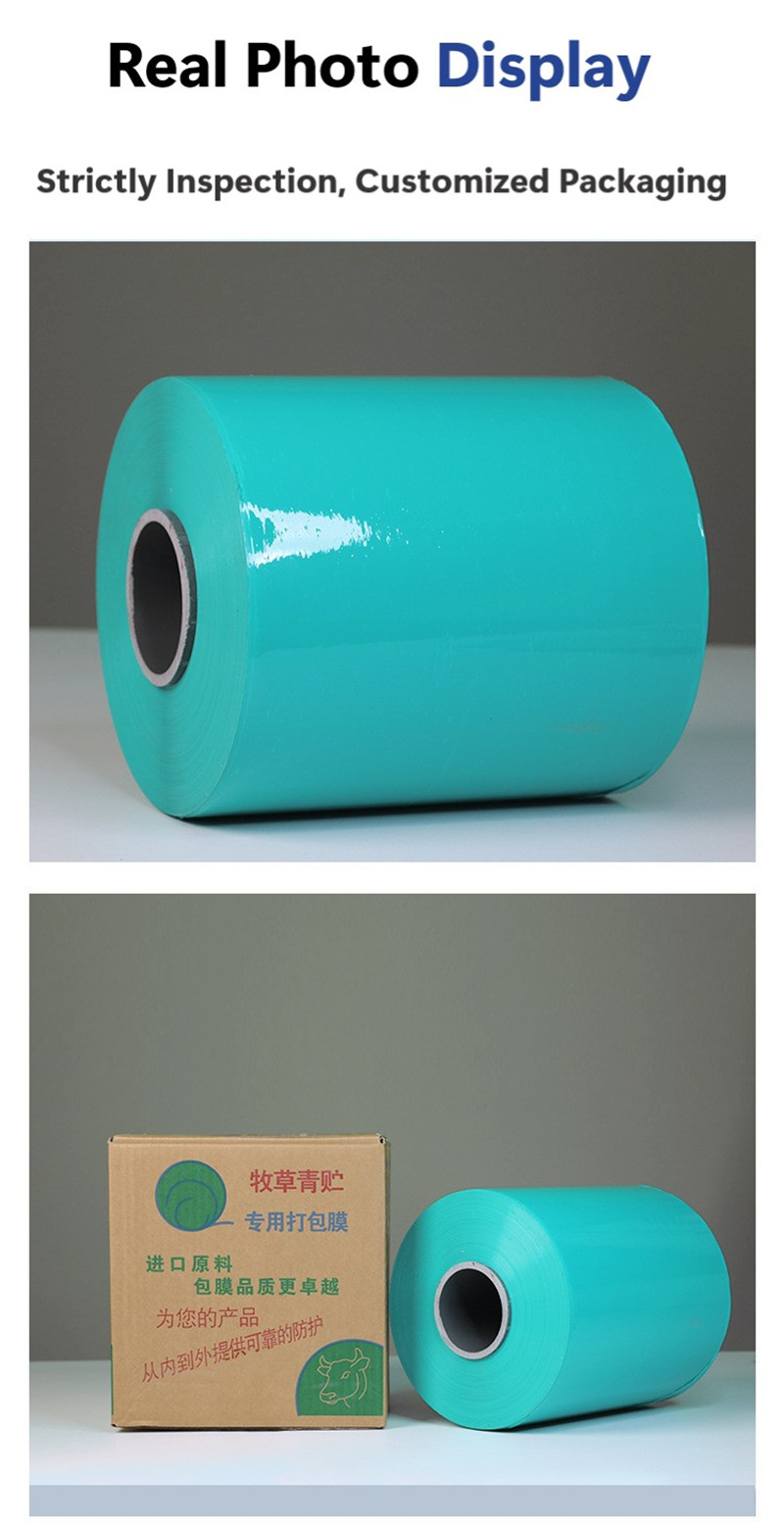

2.Strict Quality Control System:

Sources raw materials from top suppliers (Dow, Basell) to ensure film durability and barrier performance;

Implements 3-tier testing (raw material inspection → on-line monitoring → pre-shipment verification) with a 0-defect delivery rate, and products comply with ISO 9001 and EU REACH standards—qualified for export to Europe, North America, etc.

Professional R&D & Innovation Ability:

A 10-person R&D team with 8+ years of agricultural film experience, optimizing product performance annually (e.g., developing biodegradable silage stretch film for eco-friendly markets);